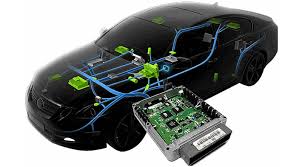

The rapid development of the automotive industry has been driven by two powerful forces: electric vehicles (EVs) and autonomous vehicle technology. These technologies have placed unprecedented focus on the electronic infrastructure of sophisticated cars — printed circuit boards. From high-speed data transfer to efficient power management, PCB hardware innovation is leading the charge for how cars will be driven in a smart, clean, and safe way.

- The Use of PCBs in Automotive Development

Electric and self-driving vehicles are far more electronics-driven than traditional combustion vehicles. Instead of being dependent on mechanical components, these whiz-bang cars rely on sensors, processors, control units, and battery management systems — all combined in a single unit on high-end printed circuit boards. The viability of these vehicles increasingly depends not just on mechanical engineering but on how engineers Design PCB layouts to be as efficient and durable as possible.

PCB design expertise has thus emerged as a key driver for car technology. Each junction in an electric car, from the battery to the traction drive system, needs high-reliability boards that will endure heat, vibration, and round-the-clock performance expectations.

- Why Automotive EVs Rely on Sophisticated PCB Hardware

The core of every EV is its battery system, and PCBs have an important function in battery management. A properly designed board balances cells, dispatches power in a safe manner, and optimises charge for maximum life expectancy. Without good PCB architecture, high efficiency and reliability in electric vehicles would be out of the question.

Autonomous cars bring in a new dimension of complexity. The vehicles use radar, LiDAR, cameras, AI chips, and high-speed communication hardware. All of them require customised PCB solutions that enable lossless and timely data transmission. To meet such demands, engineers usually rely on embedded product design services that integrate hardware, software, and system-level thinking into every solution.

- Thermal Management and High-Power PCBs

Heat management is one of the key design challenges for EVs. High currents traversing circuits, rapid charging, and motor operation all impose substantial thermal loads. Innovative thermal solutions are redesigning the way boards are developed.

New PCB technology in this category employs the latest materials that efficiently dissipate heat. By providing stable thermal management, design PCB solutions provide longer battery life, safe operation, and more reliable performance. This is particularly vital for vehicles that have been engineered to run under changing climates and extreme conditions.

- Reliability for Autonomous Systems

Reliability is not only a requirement — it is a matter of safety in the case of self-driving cars. The PCBs powering sensors and cameras must operate flawlessly, interpreting every detail within their purview accurately. A consistent design ensures high-frequency signals used by sensors like radar or communications modules do not degrade because of vibrations or changes in temperature.

This is where circuit design innovation enters. Engineers employ multilayer, high-density PCBs to prevent signal loss, reduce interference, and yield real-time performance. The engineer boards in usa have led the way in developing high-density interconnect (HDI) PCBs, which enable the integration of complex circuitry into compact footprints, perfectly suited for high-end automotive applications.

- Embedded Solutions Increasing Performance

The destiny of EVs and autonomous cars is to couple hardware and software together seamlessly. Embedded product design services offer the bridge, making each PCB not only a physical circuit but a smart system that can perform sophisticated tasks.

Whether it is managing power distribution during rapid charging or processing petabytes of data from the many sensors in autonomous driving, embedded services are the smarts that rise above the hardware. This combines systems that learn to manage real-world driving conditions and maintain cars that are responsive and reliable.

- Power Electronics and Charging Infrastructure

The most important area of innovation could well be in charging. EV adoption depends upon fast and efficient charging stations, which must be high-wattage and high-efficiency power PCBs. These boards are used to handle high-voltage conversions and regulate current for safe charging.

With the assistance of extremely efficient designs, energy loss is reduced and sustainability is increased by engineers, satisfying growing consumer demand for sustainable cars. Design PCB innovation in this category is creating new benchmarks for charging systems in order to make EVs more user-friendly and easily affordable for everyday use.

- Intelligent Sensor Integration

Autonomous driving technologies are sensor-dependent. All cameras, radar, and LiDAR modules are based on printed circuit boards that are engineered for accuracy and reliability. These boards handle high-frequency signals, interface with onboard processors, and facilitate real-time decision-making.

Embedded product design services may then be used by engineers to integrate these disparate pieces together into an integrated system. This integration of raw sensor data into comprehensible information allows the vehicle to sense environments and adjust driving behaviour in real time.

- The Role of Collaboration in Innovation

The design of cars to be future-proof is based on inter-industry cooperation. USA engineering boards are now making partnerships with automobile companies, research institutions, and providers of embedded product design services to provide complete solutions. This partnership exists in order to make new board designs not only meet performance specifications but also comply with global safety standards.

These partnerships also accelerate innovation through the merging of knowledge in application engineering, software, material science, and circuit design. The result is vehicles that not only meet today’s needs but also look forward to meeting tomorrow’s requirements.

- Making Safety Better Through PCB Hardware

Safety is at the heart of automotive engineering. In electric vehicles, PCBs in battery management systems monitor temperature, voltage, and current flow to keep the battery within limits of safety. In autonomous vehicles, PCBs ensure faultless sensor communication and data processing to avoid accidents and enhance steering.

Advanced PCB solutions, therefore, play a dual role: they provide system stability in electric drivetrain systems and enable high-level decision-making in autonomous driving. This balance is the foundation of hardware support for safety innovations.

Conclusion

Hardware technologies in PCBs are shaping the design of automotive EVs as well as autonomous vehicles. They are transforming batteries into safe power centres, enabling real-time decision-making with sensor integration, and providing efficient energy management systems for future-oriented vehicles.

With the integration of the expertise of designers of PCB layouts, the creativity of USA engineer boards, and the embedded product design services integrative approach, the automotive industry is fast embracing a smart, connected, and sustainable future.